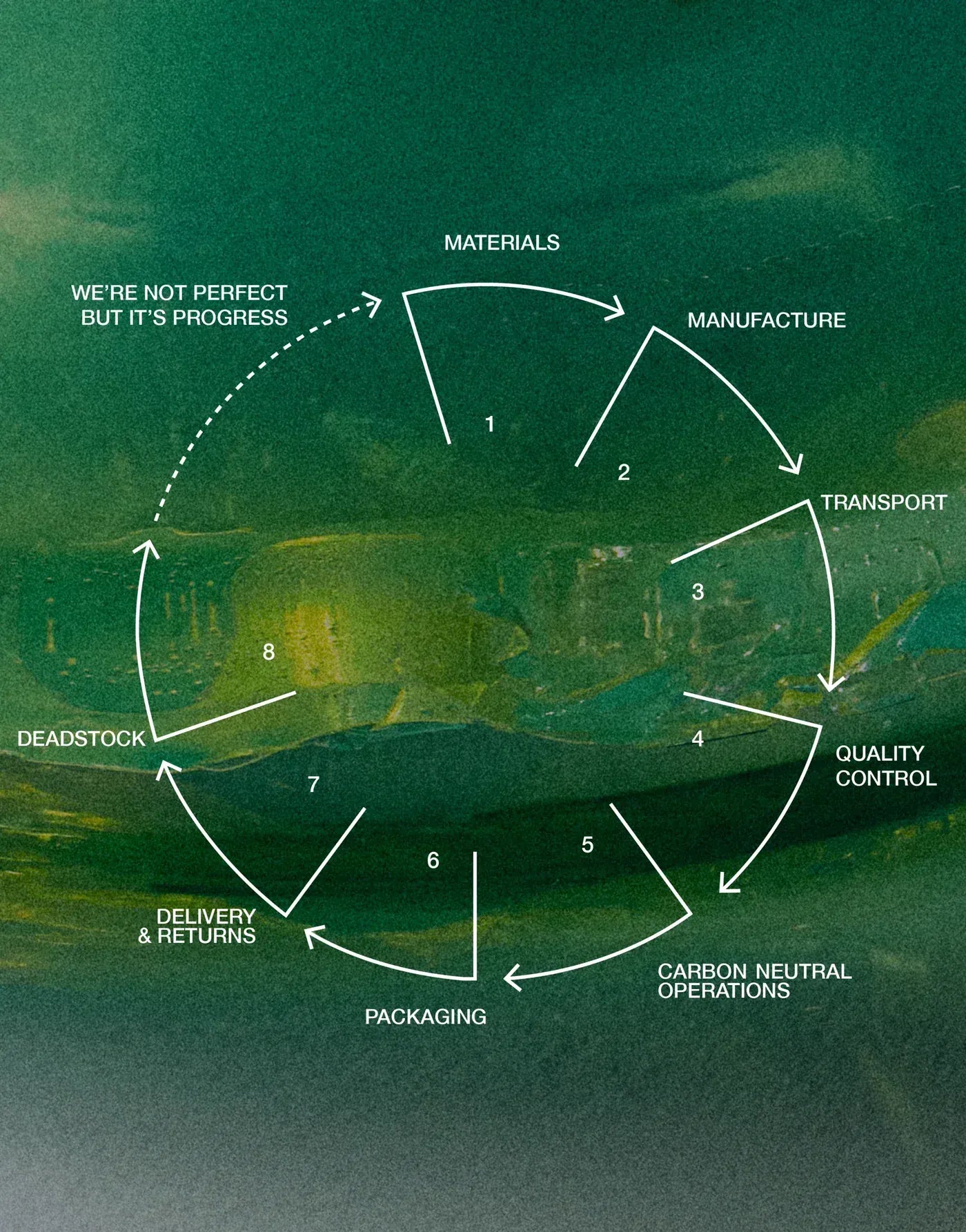

OUR PRODUCT JOURNEY

Follow the journey of how your Auluna jewellery is made, from design to delivery.

01. MATERIALS

02. MANUFACTURE

03. TRANSPORT

04. QUALITY CONTROL

05. CARBON NEUTRAL

06. PACKAGING

07. DELIVERY & RETURNS

08. DEADSTOCK

Follow The Journey

Ideas, inspirations and sketches begin in our main studio in Melbourne, Australia, and our studio in France. During the creative process, Auluna’s founder and design directors work closely together to provide a concept, look, and feel that inspire the direction of each new collection. The design team then takes these ideas and creates moodboards from all our inspirations, planning how a collection will come to life.

All our sterling silver, solid gold, and gold vermeil jewellery is made from 100% certified recycled metals. We also use conflict-free diamonds and ethical gemstones sourced from our Responsible Jewellery Council certified factories. Our 2023 pledge is to move to 100% recycled brass as well as to understand the full journey of our gemstones sources.

Find Out More

Each piece of our jewellery is handcrafted by local artisans in China, India, and Thailand. As of April 2023, together with our six partner factories, we have been certified by the Responsible Jewellery Council’s Code of Practices, following ethical and responsible standards. Some of our factories have also recently transitioned to green energy from renewable sources to help reduce carbon emissions, while others plan to follow.

All our newly crafted jewellery pieces are shipped back to us in Australia by our suppliers via air freight, using recyclable packaging and biodegradable bags. Since January 2023, they have stopped using plastic bags for shipments to us.

Everything we make is rigorously tested as part of our quality control process — from pre-production samples to wear tests — to ensure it’s up to our high standards. We also have a dedicated QC team in every factory to check each and every piece throughout the production process. If it gets the green light, it’s given its final sign-off.

Our Melbourne warehouse, head office, service store, and Paris pop-up and franchise locations are now carbon neutral,

with emissions offset through nature-based community and renewable energy projects.

Since early 2023, we have also transitioned our production operations toward renewable green energy.

Three of our six partner factories — increasing to four as of May 2023 — are now powered by renewables,

and our London warehouse operations have also begun sourcing renewable energy.

The packaging we use to ship our customer orders is recyclable, biodegradable and re-usable, produced in an audited factory in China and sent to us by sea freight. We also offset the carbon emissions from our packaging operations with biodiversity projects focused on reforestation and rainforest protection.

We've been offsetting the carbon emissions from our customer deliveries and returns since 2021. We know it's not enough to pay to compensate for these emissions, so a goal for 2023 is to explore greener delivery options for our customer orders to reduce this footprint as much as possible.

Auluna pieces that can't be re-sold or donated — usually from being broken and irreparable — are upcycled into new pieces through partnerships with design colleges (The Deadstock Project). We also work with rental brands to ensure our jewellery is only worn when needed, and not purchased and wasted.

Any remaining deadstock is then sent off to be scrapped and turned into new recycled metals. This year our goal is to ramp up and continue to look to a more circular future.

SUSTAINABLE MATERIALS

FIND OUT MORE

A CIRCULAR FUTURE

SEE OUR PROGRESS

OUR PRODUCT JOURNEY

LEARM MORE

OUR 2025 GOALS

read our pledge